+375 0212 67-32-33

+375 0212 66-35-83

+375 0212 66-93-18

A WIDE CHOICE

BOARD MATERIALS

OUR PRODUCTS ARE ALWAYS OF THE HIGHEST QUALITY!

ПОЗВОНИТЕ НАМ:

НАПИШИТЕ НАМ:

Скачайте наши каталоги:

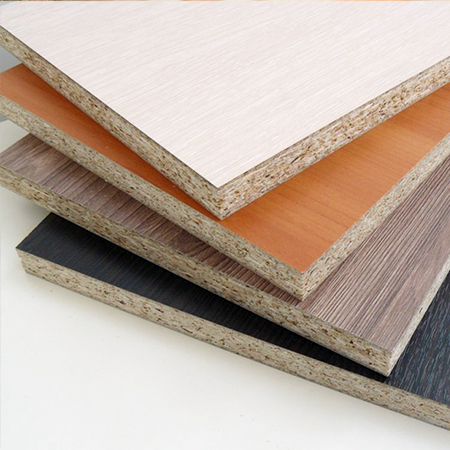

LAMINATED CHIPBOARD HAS ALL THE ADVANTAGES OF A STANDARD CHIPBOARD, BUT IT IS PRESENTED IN A LARGE NUMBER OF COLOR SOLUTIONS. MODERN PRODUCTION TECHNOLOGY MAKES IT POSSIBLE TO GIVE THE SURFACE OF THE PLATE THE PROPERTIES OF THERMOSETTING PLASTIC WITH HIGH RESISTANCE TO MECHANICAL AND CHEMICAL INFLUENCES.

THIN CHIPBOARD IS A MATERIAL WITH A THICKNESS OF 6-8 MM, WHICH HAS HIGH STRENGTH IN BENDING AND STRETCHING. THIN CHIPBOARD HAS A LOW FORMALDEHYDE EMISSION CLASS-E1, WHICH MAKES THIS MATERIAL SAFE FOR HEALTH, AND ALLOWS IT TO BE USED FOR THE PRODUCTION OF ENVIRONMENTALLY FRIENDLY FURNITURE, CONTAINERS AND PACKAGING.